Services

Expert consulting based on digital manufacturing solutions

Manufacturing simulation

Creating and validating “factory of the future” concepts using the digital twin model: Our experts use the latest development systems to create a multi-purpose simulation of the digital factory: material flow proof of concept, material flow simulation eligible for validation, digital twin model, full-detail model for virtual deployment. Recommended for manufacturing companies, equipment manufacturers and system integrators to become confident with their investments by getting a more detailed and precise view of the expected operation early during the design phase.

Analyzing and optimizing manufacturing processes

Modeling the entire production lifecycle is primarily relevant for large enterprises (with a focus on Business Process Consultancy and Reengineering). The lifecycle doesn’t miss production optimization, intralogistics and stock management processes. We can conduct the design of control engineering systems of existing and planned complete production lines, elaboration of conceptual modernization plans, complemented with production and process simulation. We can also validate investments, create roadmaps and high-level budgets for investments, and create comparisons of the legacy and the planned system for factory improvements. Our colleagues use state-of-the-art digitalization solutions for the brainstorming and validation phases, supplemented by a complete documentation required for decision-making.

Engineering services

Engineer consulting

Our skilled experts offer traditional consulting in automation and construction engineering. Having engineers in-house for almost all relevant automation areas, such as machinery, electricity and software development brings competitive advantage to us. We also have a great track of records in drive control, industrial robots, safety and vision systems, too.

Compiling specifications of production machinery and specialized equipments for buyers

The set of technical tasks to perform can often not be defined exactly in front, or a longer term collaboration serves the basis of a joint development. Whether it’s an ad-hoc service or a collaboration spanning over years, we’ll be able to come up with a solution. We can help in compiling technical, business and operational terms and conditions, developing proof of concept simulations, as well as in creating prototypes or MVPs.

Turnkey industrial systems

Complete machinery design and production

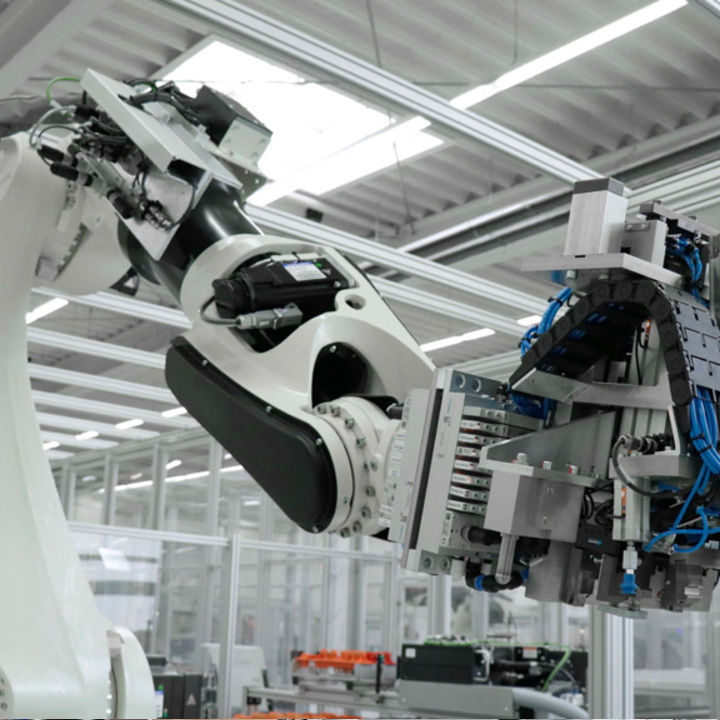

Our company offers turnkey delivery of the following industrial systems from designing the operational concept (perhaps digitally) to the full implementation and production:

- Special equipments, automated manufacturing and assembly machinery

- Robot cells, closed production cells with path movements

- Test equipments

- Traditional intralogistics systems

- AGV and mobile robotics solutions

- Complex equipment modernization (to reach higher level of automation or speed)

- Production line expansion (to reach higher productivity or implement new features)

Automation and equipment design services

- Process evaluations, rationalization and digitalization of production processes

- Developing proof of concept simulations

- Expert advice for production processes, designing conceptional machines and parts

- Micro and macro level simulation of new solutions, ideas and visions

- Compiling requirements specification for new manufacturing environments

- Creation of REPOC, prototypes and MVPs

- Designing and manufacturing machine units, instrumenting for IIoT, retrofitting

- Virtual deployment services

- On-premise engineer and technician consulting

Drive&Motion solutions and distribution

Lenze motion-control solutions

From November 2023 in a performance partnership IDM-Systems Zrt. delivers spare parts for Lenze drive and motion products and systems and offers corresponding services.

The covered product lines are: motors, motors with gearboxes, controllers, motion control plc-s, inverters, gearboxes, accessories, software.

IDM-Systems Zrt. is ready to serve its clients with additional engineering and technical services as a payed support. Furthermore our customers can count on us in modernisation and retrofit projects regarding entire machines and complex drive and motion systems.

Discover the product palette and the motion control solutions on the manufacturer’s webpage!

For more information and a price quotation please contact us!

E-mail: lenzesupport@idm-systems.hu

Phone: +36 70 477 0833

CMZ distribution

Beginning with autumn 2023 - as certified partner in Hungary - we started the distribution of the drive and motion products of the Italian company CMZ. The portfolio consists of servo drives, controllers, step motors, industry branch (food, printing, paper, textile, glass, sheet metal) specific software solutions. Discover the products on the website of CMZ! (https://www.cmz.it/en )

For more information and a price quotation please contact us!

E-mail: cmzsupport@idm-systems.hu

Phone: +36 70 477 0833

Using the servo drive configurator you can chose the most suitable product for your application:

https://www.cmz.it/dbmotors/Main.php

Training and post-delivery services

Training

We primarily take on customer trainings for our own solutions, and also offer trainings customized for customer requirements. Recommended for manufacturing companies, equipment manufacturers and system integrators to become confident with their investments by getting a more detailed and precise view of the expected operation early during the design phase.

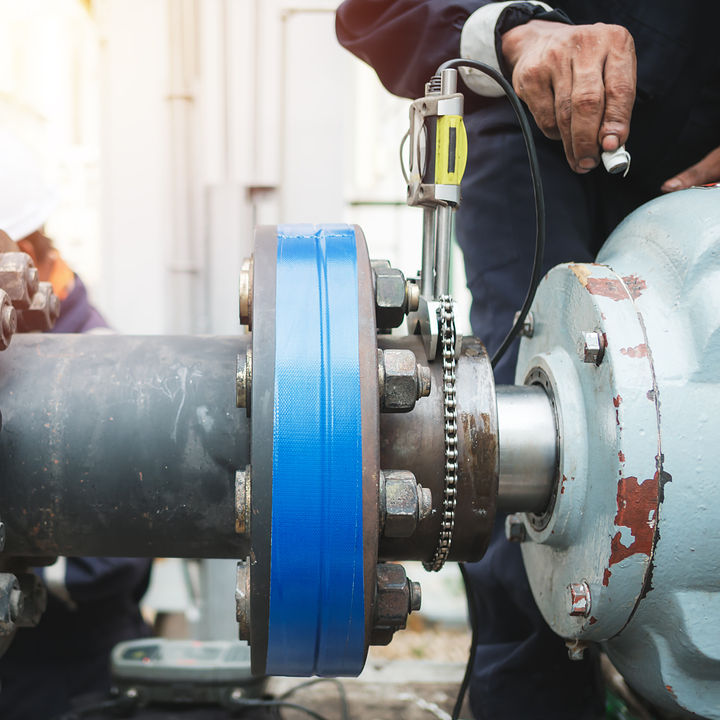

Post-delivery services

Scheduled maintenance: Our primary focus is on the mandatory scheduled review and inspection of our systems, with the contribution of technicians and engineers.

Level 2 and 3 support, remote failure analysis: Digital manufacturing solutions allow for remote failure analysis, sometimes even for precisely locating the root of the failure. Industrial 5G communication will soon enable real-time monitoring of data using the digital twin of the physical system.